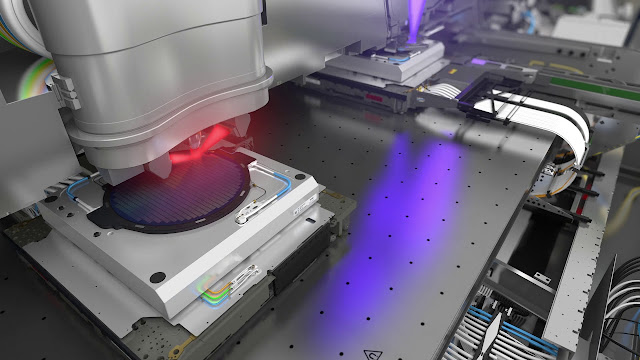

Wafer Laser Marking CA offers a range of features that provide users with high accuracy marking. The process is also very energy efficient and requires low maintenance, making it an ideal choice for a wide range of applications. Semiconductor fabrication and packaging represent challenging marking applications, with small marks often required on very thin device geometries. Near IR laser markers are used for this type of work, as they are capable of producing shallow marks without damaging surrounding material.

High Precision

Wafer

Laser Marking CA is a system combining robotic part handling, automated part

alignment, a laser source, beam delivery optics, and control and interface

software. The system performs high-speed silicon wafer etching, marking, and

glass scribing for NGS Flow Cell production.

The

system is configured to accept a predetermined size wafer and automatically

position the wafer relative to the laser marker along a direction substantially

perpendicular to the plane of the wafer. The system may also include a second

positioning subsystem for automatically positioning the wafer relative to the

laser marker along another direction substantially perpendicular to the plane.

The process

500 receives a scribe pattern from an imaging sensor, saves the scribe pattern

in a memory, and performs marking on the back side of the wafer according to

the scribe pattern as recognized by the imaging sensor. The process 500 then

cuts the wafer from the back side based on the scribe pattern as recognized by

the imaging sensors.

Low Energy Consumption

Wafer Laser

marking is a highly important process in the semiconductor

industry because it allows manufacturers to track wafers through the various

stages of the manufacturing process. It also helps prevent damaged and

defective chips from being distributed.

Low

energy consumption is one of the primary benefits of using a laser for marking.

This is because the energy beam is so precise that it can exert just the right

amount of power without dispersion, ensuring that marks are not compromised.

Moreover,

lasers are used to mark materials that cannot be engraved with conventional

marking systems. This is especially the case with sensitive silicon wafers,

which can be damaged if they are cut by a conventional cutting device.

In

addition, lasers can be used to mark a variety of materials, including plastics

and metals. In this way, manufacturers can create high-quality marks that are

easy to read.

Low Maintenance

Unlike

other marking methods like dot-ping, acid etching, and electrophoresis, laser

marking does not damage the substrate. This makes it an ideal solution for

wafer fabs because it ensures wafer traceability.

It

also provides an excellent scalability option for production. It can be

operated with a variety of wafer sizes, including those ranging from 4′′ to

8′′.

Laser

direct part marking (LDPM) is a fast and reliable method of delivering

high-quality, long-lasting code symbologies on any metal, plastic or organic

material. Datalogic has a broad portfolio of laser markers to choose from,

including fiber, CO2, ND:YAG, UV, and green.

Moreover,

laser markers are known for their low maintenance compared to other marking

technologies. They are a non-contact process that allows for minimal mechanical

wear between the marking system and the target material, which helps you reduce

costs and downtime.

Easy to Operate

Wafer Laser

marking silicon is an easy to operate process. It does not use

any chemicals or inks, so it is also much safer for the environment. Another

great feature of laser marking is that it's a lot faster than other methods. In

fact, entire stacks of wafers can be marked in a matter of minutes.

The

laser marking system is extremely accurate, so even the tiniest details are

always precise and consistent. This is why laser marking is one of the best

choices for semiconductor manufacturers.

Laser

marking systems come in a variety of different sizes and styles. Some are

designed for system builders and production line integration while others are

self-contained, table-top systems. They are also ideal for 3D marking,

engraving, and mark serialization.